Table of Contents

Where can hydraulic systems be found?

Hydraulic systems are powerful machines. They use pressurized fluid to create force and movement. They are incredibly useful and are found in many everyday machines and vehicles. Hydraulics are everywhere. They power your car’s brakes and lift heavy loads with construction equipment. This article will explore hydraulic systems. It will cover where to find them, how they work, and their importance.

What is a hydraulic system?

A hydraulic system is a machine that uses pressurized fluid to perform work. These systems have four basic parts: a pump, hydraulic fluid, valves, and cylinders. The pump pushes hydraulic fluid through the system. It travels through hoses and valves, making machines move. Hydraulic fluid is pushed into a hydraulic cylinder. It moves a piston inside, generating enough force to lift or push heavy objects. This is why construction equipment, like cranes and bulldozers, often uses hydraulic systems.

Hydraulics are also found in everyday objects like elevators, dishwashers, and office chairs. Hydraulic systems are useful. Their fluid transmits pressure without losing force.

Hydraulic Systems Found in Everyday Life

Hydraulic systems are all around us. They can be found in machines and devices we use every day. Let’s look at some examples.

HydraulicLet’sCars

Most modern vehicles rely on hydraulic systems for their braking systems. Hydraulic brakes use fluid to transfer pressure from the pedal to the pads. Pressing the brake pedal pushes hydraulic fluid through tubes and valves. This makes the brake pads press against the wheels and stop the car.

Another example is power steering. It’s in many vehicles to ease turning the steering wheel. A pump sends hydraulic fluid to the steering mechanism. This lets the car steer with little effort.

Hydraulic Systems in Office Chairs

Did you know your office chair might use hydraulics? Many office chairs have a hydraulic system that allows you to adjust the seat height. Pushing the lever on the chair raises or lowers the seat. A hydraulic cylinder inside the chair moves to do this. This is an example of hydraulic power used in everyday office equipment.

Hydraulic Systems in Amusement Parks

Hydraulics are also used in amusement parks. Rides like roller coasters, Ferris wheels, and drop towers often use hydraulic systems. Amusement park rides, like the free-fall tower, use hydraulic cylinders. They raise and lower riders quickly and safely. The hydraulic fluid creates pressure. It pushes the pistons, which control the ride’s movement.

Hydraulic Systems in Construction and Heavy Machinery

Hydraulic systems are widely used in construction equipment and heavy machinery. They can lift and lower heavy loads easily. This is vital for tasks that are too dangerous or impossible with manual labour.

Hydraulic Systems in Excavators

The excavator is a common example of a hydraulic system in construction. Excavators use hydraulic rams to extend and retract their arms. The arms can raise and lower heavy loads by pumping hydraulic fluid into cylinders. Construction workers can dig, move dirt, or carry large materials. Hydraulic pumps are the key component in these systems. They move the fluid through the machine’s systems in cranes and forklifts.

Also Read: The Art of Managing Cyber Threats: Practical Strategies for Today’s Digital Landscape

Cranes, backhoes, and forklifts also rely on hydraulic machines. These machines use hydraulic cylinders to lift and lower heavy items, such as construction materials and pallets. For instance, in a crane, hydraulic fluid extends the boom, allowing it to reach higher or farther.

Heavy equipment, like dump trucks and bulldozers, uses hydraulics to raise and lower their parts. A hydraulic motor drives the equipment, allowing for smooth and precise load control.

Hydraulics in Manufacturing and Commercial Equipment

Hydraulic systems are not just for heavy machinery. They also play a key role in manufacturing and commercial equipment.

Hydraulic Presses

In factories, hydraulic presses are used to shape and form materials. These machines use hydraulic fluid to apply pressure to a material, like metal or plastic. They generate massive force. A hydraulic press can stamp, mould, or cut materials. It is one of the most powerful machines in manufacturing.

Hydraulic Systems in Dishwashers

Believe it or not, dishwashers use hydraulic power, too. A hydraulic pump pushes water through pipes and jets, spraying it onto dishes to clean them. The pressure in the system allows water to flow through narrow openings at high speed, helping to remove food and grime from your dishes.

Hydraulics in Elevators

Elevators also rely on hydraulic systems to move up and down. In a hydraulic elevator, a pump sends hydraulic fluid into a cylinder beneath the elevator car. The fluid moves the piston inside the cylinder, lifting the elevator. When the elevator needs to go down, the hydraulic fluid is released, allowing gravity to lower the car.

How Do Hydraulic Systems Work?

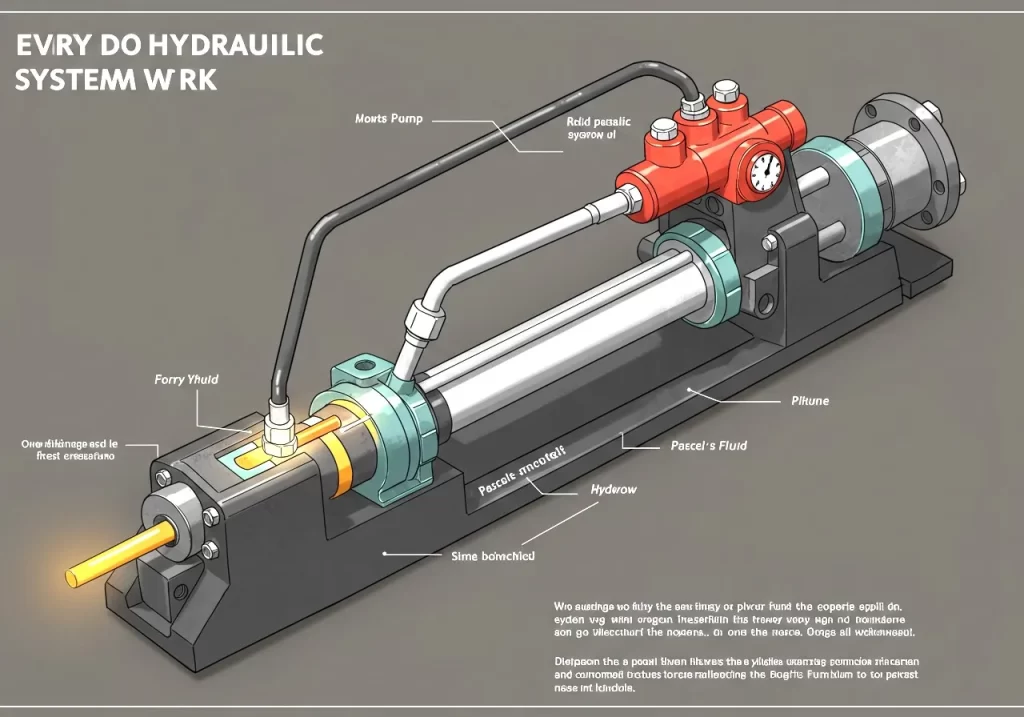

Every hydraulic system relies on one principle. Hydraulic fluid cannot be compressed. This means that when force is applied to the fluid, it moves through the system, transferring pressure evenly.

Hydraulic systems rely on a hydraulic pump to move the fluid. The pump pushes the fluid into a hydraulic cylinder, exerting pressure on a piston. The piston then moves, creating a force that can be used to lift, push, or move heavy objects.

Pascal’s Principle states that pressure applied to a fluid is transmitted equally in all directions. A small amount of force applied on one side of a hydraulic system can result in much greater force on the other side.

Why are hydraulic systems so useful?

Hydraulic systems are incredibly powerful and versatile. They can generate immense force in a compact space, making them ideal for heavy machinery and equipment. Here are some reasons why hydraulic systems are so useful:

- High Power in Small Spaces: Hydraulics can generate much force in a small area. This is important for heavy equipment like cranes, excavators, and forklifts that need to lift or move heavy loads.

- Smooth and Precise Control: Hydraulic systems allow for smooth and precise movements. It’s critical for machines like ski lifts, excavators, and amusement park rides. They need precise control.

- Versatility: Hydraulic systems can be used in various industries, from construction to manufacturing. They are used in everything from hydraulic tools to large construction machinery.

The Future of Hydraulic Systems

Hydraulic systems are becoming more efficient and versatile with advancing technology. New tech and designs for hydraulic fluids are making these systems greener and more energy efficient. Yet, hydraulics remain vital in many industries. Their use will likely grow as more businesses see the benefits of fluid power.

Hydraulic Repair and Maintenance

Like any machine, hydraulic systems require regular maintenance to function properly. It involves checking for leaks, replacing old fluid, and ensuring the pump and cylinder work. Regular upkeep prevents breakdowns and keeps systems working safely and efficiently.

If you need assistance with hydraulic repair, it’s important to contact a professional. Proper care can extend the life of your hydraulic equipment and keep it running smoothly.

Hydraulic cylinder system illustrating fluid mechanics.

Hydraulic systems are vital to modern equipment. They power many everyday machines, like construction equipment, amusement rides, and elevators. They lift heavy objects and enable precise movements, making tasks easier and more efficient. Compact hydraulic systems are vital in industries such as construction and manufacturing. Whether in daily life or heavy machinery, hydraulics are essential and here to stay.