Table of Contents

Introduction to CNC Technology

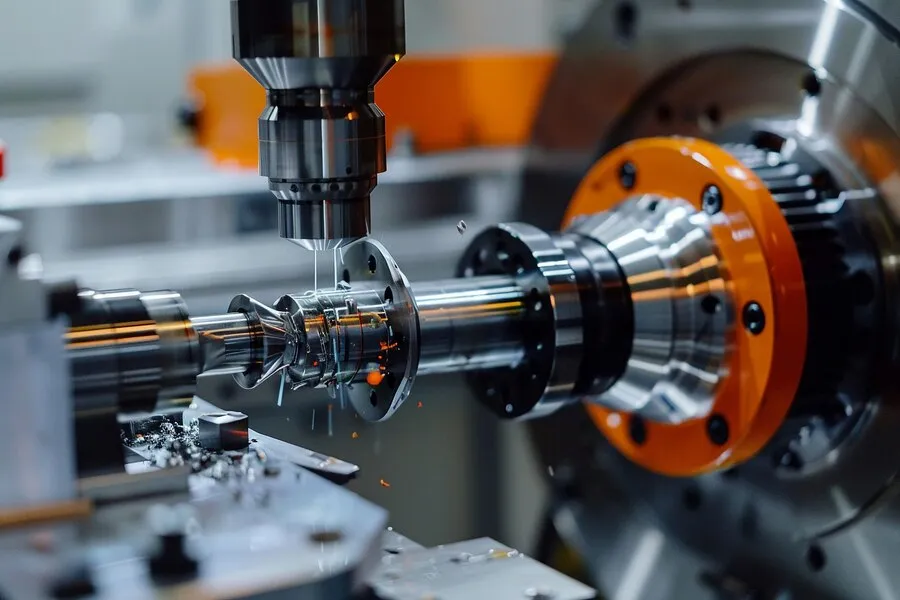

The use of axis machining is on the rise offering greater capabilities compared to traditional three-axis machines. Multi-axis CNC machines offer enhanced production possibilities for parts elevating the efficiency and adaptability of manufacturing processes. The added axes enable increased flexibility. Reach is crucial for crafting components with precision. By incorporating drop replacement parts machining accuracy has never been more attainable and streamlined. Real time monitoring is also gaining momentum in the industry empowering manufacturers to monitor machine statuses and production. This real-time tracking facilitates prompt identification and rectification of any irregularities ultimately boosting productivity and minimizing downtime. Noteworthy advancements have also been made in efficiency with modern spindles engineered to operate at speeds with superior precision for swifter and more precise cutting tasks.

Current Trends in CNC Technology

Manufacturers are heavily investing in machinery for executing highly precise operations while optimizing processes through self-calibration and real-time data analysis. These smart systems enhance productivity. Cut costs by reducing waste and improving machine performance. The shift towards machinery is predominantly fueled by the industry’s demand, for increased workload capacities, reduced downtime, and overall operational efficiency. Additionally, the use of acu-rite DRO replacement parts plays a crucial role in maintaining the accuracy and reliability of these advanced systems.

Innovative Materials in CNC Machining

The use of cutting edge materials, in CNC machining is a trend that is reshaping the industry. Industries like aerospace, automotive, and medical are looking for components made from materials that can withstand conditions while performing effectively. These materials, such as carbon fiber composites, titanium, and specialized alloys offer strength-to-weight ratios and resistance to corrosion and high temperatures.

For example the aerospace industry relies heavily on carbon fiber composites for their properties and high strength for fuel efficiency and structural integrity. Similarly titanium is a choice for implants due to its biocompatibility, strength and resistance to corrosion. These advanced materials not improve the durability and performance of parts. It also allows for the creation of unique customized components that are difficult to achieve using traditional materials.

An exciting development in this field is the emergence of self healing materials. These innovative materials have the ability to repair themselves when damaged significantly extending the lifespan and reliability of parts. This breakthrough in material science reduces the need for replacements and maintenance resulting in cost savings and improved sustainability, in manufacturing processes.

Automation and AI Integration

The integration of automation and artificial intelligence (AI) is revolutionizing CNC operations by enhancing task performance and management. Automation systems and robotics have been seamlessly incorporated into CNC machining improving efficiency minimizing errors and maintaining consistent quality. Robots now handle tasks, like loading/unloading materials and executing tool changes allowing human workers to focus on creative responsibilities.

AI plays a role in maintenance, workflow optimization and energy management. By analyzing amounts of data from machining processes AI can anticipate machine breakdowns and plan maintenance activities in advance reducing unplanned downtime and extending equipment lifespan. Moreover, AI driven analytics help manufacturers optimize energy usage by identifying and eliminating inefficiencies in production processes resulting in cost savings and environmental advantages.

The continuous learning ability of AI contributes to decision making and process enhancements. Intelligent algorithms offer insights into process optimization, quality assurance and resource allocation to ensure CNC operations are as efficient and productive as possible. With the advancement of AI technology, its integration into CNC systems will further boost automation capabilities fostering innovation and competitiveness within the manufacturing sector.

Focus on Sustainability and Environmental Impact

Sustainability is increasingly important in CNC machining. The industry is embracing energy machinery and eco-friendly production methods to reduce its impact, for a more sustainable future.

Manufacturers are increasingly turning to bioplastics and other eco-friendly materials that can be recycled or naturally decomposed once they’ve served their purpose. This shift does not help cut down on waste. Also promotes a more sustainable approach supporting a circular economy.

For example, the use of bioplastics, in CNC machining comes with advantages, such as reducing carbon emissions and lessening reliance on fossil fuels. Moreover the incorporation of materials like recycled aluminum and reclaimed timber in crafting visually appealing components underscores the significance of practices in manufacturing. Embracing eco materials and production methods not only conserves natural resources but also meets the rising consumer demand for environmentally conscious products.

Energy efficiency plays a role in CNC machining practices. Modern CNC machines are engineered to operate with energy consumption without compromising performance, which helps cut expenses and lessen environmental impact. Implementing energy-saving strategies like optimizing machine usage and minimizing time further contributes to manufacturing practices. By prioritizing sustainability the CNC industry can pave the way for long-term growth and success while meeting consumers increasing preference for options.

Future Advancements

The future of CNC technology appears promising with developments on the horizon poised to transform the industry landscape. Progress, in quantum computing, nanotechnology, and advanced robotics is expected to enhance the capabilities and applications of CNC machines. These new advancements are set to make manufacturing processes quicker, more accurate, and cost-effective leading to increased growth and competitiveness, in the industry.

Take quantum computing for instance. It has the potential to boost power allowing for intricate simulations and optimizations in CNC processes. This technological advancement could simplify the creation and production of components ultimately reducing both the time and costs associated with manufacturing. In a vein, nanotechnology enables the manipulation of materials at a level that results in precise and intricate parts that were previously unattainable. This breakthrough opens up opportunities in sectors like electronics, medical devices, and aerospace where precision and miniaturization play roles.

Another area poised for growth is robotics with robots becoming smarter more adaptable and capable of handling complex tasks. By integrating robots (cobots) with CNC machines, automation, and productivity in manufacturing processes can be further improved. Cobots can collaborate with operators by taking on hazardous tasks while humans focus on strategic decision-making and creative endeavors. This partnership, between humans and robots fosters a working environment that promotes efficiency while driving innovation and competitiveness within the CNC industry.

Challenges Facing the CNC Industry

Despite progress made so far and the promising future ahead, the CNC industry encounters various challenges that require attention to ensure continued growth and innovation.

One of the hurdles faced is the expenses involved in acquiring and keeping advanced CNC machinery. These complex machines require an investment, which can pose a significant obstacle, for smaller companies. Additionally, the ongoing costs linked to machine maintenance and upgrades can put a strain on resources.

Another issue stems from the requirement for operators to oversee and maintain these machines. Technological progress necessitates training and education to ensure that the workforce stays abreast of the CNC technologies and techniques. This demand presents a challenge for both employers, who must invest in training programs, and employees who must constantly adapt to tools and methodologies.

Furthermore, the increasing intricacy of CNC systems can result in heightened difficulties such as troubleshooting and process optimization. Achieving efficient operations across all aspects of CNC requires an understanding of both the machinery itself and the production processes. Tackling these challenges is essential for maintaining competitiveness and driving innovation in the CNC sector.

Also Read: Oil and Gas Industry Prime for Outsourced Wireline Providers

Final Thought

CNC technology sits at the forefront of manufacturing with its future poised for growth and innovation through embracing new advancements and practices. By staying informed about emerging trends and embracing state-of-the-art technologies the CNC industry can meet the changing demands, across sectors.

Ensuring the long-term success and efficiency of CNC machining relies, on adopting practices and tackling industry challenges. The continuous evolution of CNC technology will have an transformative impact, on manufacturing processes and the global industry.