Table of Contents

Introduction

The oil and gas industry relies heavily on the seamless operation of its vast pipeline network. Any disruption, whether through blockages or corrosion, can lead to major operational setbacks, increased costs, and safety hazards. Among the most reliable preventive maintenance strategies are effective cleaning pigging solutions for oil and gas pipelines. These methods allow operators to maintain pipeline cleanliness and efficiency without shutting down operations, thereby maximizing productivity and minimizing risk.

Pipeline pigging is not just a cleaning process—it’s a critical aspect of pipeline health management that mitigates issues before they grow into expensive failures. By regularly deploying specific types of pigs to clean, inspect, and maintain pipelines, operators can ensure each asset performs at its best, contributing to overall energy infrastructure reliability.

Understanding Pipeline Pigging

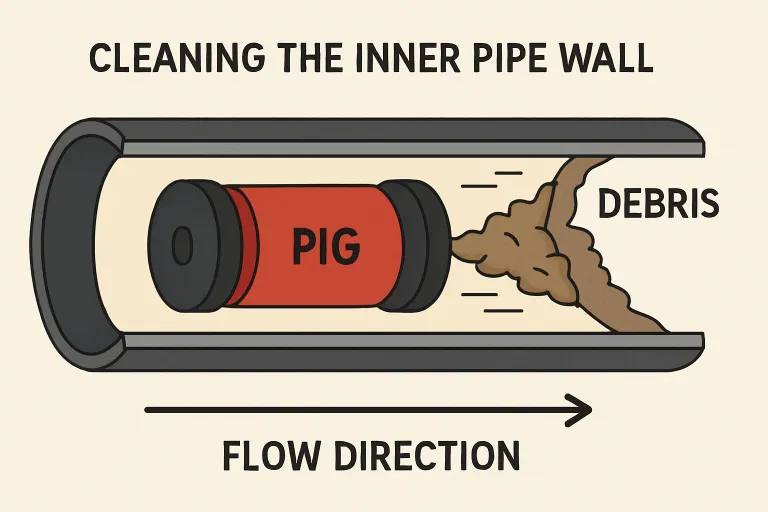

Pipeline pigging involves inserting specialized devices known as “pigs” into pipelines, which then traverse the length of the pipe powered by product flow. As they travel, pigs perform crucial functions such as removing debris, scraping buildup, surveying the pipe wall for defects, and even separating different products in multiproduct pipelines. The process is non-intrusive and can be executed without halting the normal flow of oil or gas, making it a crucial tool for continuous maintenance and inspection.

This technique provides consistent results for both old and new pipelines, serving as a primary method of condition-based monitoring. Pigging sessions prevent the gradual buildup of materials such as wax, sludge, and asphaltenes. The removal of these obstructions ensures smooth product flow through the pipeline, boosts throughput, and minimizes the energy required to pump the material.

Benefits of Regular Pigging

- Enhanced Flow Efficiency: Pigging sessions prevent the gradual buildup of materials such as wax, sludge, and asphaltenes. The removal of these obstructions ensures smooth product flow through the pipeline, boosts throughput, and minimizes the energy required to pump the material.

- Corrosion Prevention: Moisture and chemical contaminants pose serious corrosion risks. Regular pigging removes these agents, decreasing the rate of pipe degradation and extending the pipeline’s operating life.

- Early Detection of Defects: Intelligent pigs can spot cracks, dents, and wall thinning. Early detection gives pipeline operators the chance to act preventively, minimizing costs and reducing the danger of catastrophic failures.

- Regulatory Compliance: Keeping the pipeline clean and in good repair helps companies comply with evolving environmental and safety regulations, supporting responsible operations and public trust.

Types of Cleaning Pigs

The choice of cleaning pig is influenced by the type and severity of pipeline contaminants. Here are three widely used options:

- Foam Pigs: Soft, adaptable pigs that effectively dislodge loose debris and help dry pipeline interiors following hydrostatic testing.

- Brush Pigs: Equipped with hard-bristled brushes, these pigs are particularly effective at removing stubborn deposits or partial blockages from the pipe wall.

- Magnetic Pigs: By using strong magnets, these pigs collect ferrous debris such as rust, making them ideal for pipelines where corrosion products are an issue.

Implementing an Effective Pigging Program

Building and maintaining a robust pigging program involves several strategic steps:

- Assessment: Begin by analyzing the pipeline’s age, materials, and service records to identify vulnerabilities and maintenance needs.

- Selection: Choose the appropriate pig types for specific cleaning tasks, considering pipeline diameter, length, and deposit type.

- Scheduling: Develop a regular pigging calendar to target buildup before it becomes problematic. This schedule should be flexible and responsive to changes detected during monitoring.

- Monitoring: Employ data-logging pigs to collect visual and sensor data during each run. Adjustments to the cleaning schedule or pig type can then be made based on real-time findings.

Challenges and Solutions in Pigging Operations

Despite its many advantages, pigging can present operational challenges. Pipelines with complex layouts, including bends or diameter changes, can hinder pig movement or cause pigs to become lodged. Modern pig designs address these by incorporating articulations and variable geometry to navigate even the most difficult pipeline paths.

- Complex Pipeline Geometries: Innovations in pig design enable custom pigs to traverse tight bends and multiple diameters, ensuring comprehensive cleaning across all pipeline segments.

- Stubborn Deposits: Pipelines with severe scaling or highly viscous deposits may require heavy-duty pigs equipped with scrapers, brushes, or abrasive materials to restore internal diameter.

- Tracking Difficulties: Pig tracking systems using radio transmitters and receivers ensure constant pig location awareness, preventing pigs from being lost in line and facilitating quick retrieval and troubleshooting.

Innovations in Pigging Technology

The advent of “smart pigs” has transformed pipeline integrity management. These intelligent devices can detect pipeline wall thickness, corrosion, weld integrity, and geometric irregularities, all while transmitting detailed data to operators in real time. Integrated with GPS and state-of-the-art sensors, these smart pigs enable predictive maintenance, reducing emergency repairs and lowering overall risk.

According to a recent study published in Nature, advancements in sensor technology and data analytics have significantly improved the accuracy and efficiency of these pipeline inspection tools, allowing operators to identify potential failures before they escalate into costly incidents. Click here to recent post about Decluttering Made Easy: When and Why to Use a Roll-Off Dumpster.

Conclusion

Cleaning pigging solutions have become indispensable tools in the modern oil and gas industry. Regular, well-planned pigging programs keep pipelines flowing efficiently, allow for early risk mitigation, support compliance, and ultimately lower costs for operators.

By embracing advances in pigging technology and tailoring programs to specific pipeline systems, companies can achieve superior operational performance and maximum pipeline longevity.