Table of Contents

Key Takeaways:

- Understanding the various types of commercial ladders and their specific applications is essential for ensuring workplace safety.

- Proper ladder selection, inspection, and usage can significantly reduce the risk of ladder-related injuries.

- Regular training and adherence to safety guidelines are essential for maintaining a safe working environment.

Introduction

Creating a safe workspace is a vital responsibility, especially when duties involve working at heights. Every year, many workplace accidents are linked to improper ladder selection and unsafe practices, underscoring the need for careful ladder selection and proper training. The right equipment not only reduces accident risk but also ensures efficiency and compliance with regulations. To support these objectives, platforms and ladders offer a range of solutions tailored to various workplace requirements, enabling businesses to prioritize safety and effectiveness.

A well-informed choice in ladders can mean the difference between a routine task and a workplace incident. Selecting the correct ladder type, understanding duty ratings, and maintaining equipment are foundational steps toward a safer environment for any workforce. In the sections below, we’ll explore types of commercial ladders, safety standards, inspection protocols, and key training tips for optimal performance and security.

Employers and workers alike benefit from recognizing how even small details—like the ladder’s material or duty rating—can influence both outcomes and compliance. When paired with ongoing oversight, these details lower liability and help organizations promote a culture of unwavering safety on the job.

Comprehensive safety programs must not only focus on equipping staff but also on continual education and adaptation to new standards. The evolving nature of workplace safety underscores the importance of resources that keep employees informed and prepared at all times.

Understanding Ladder Types and Their Applications

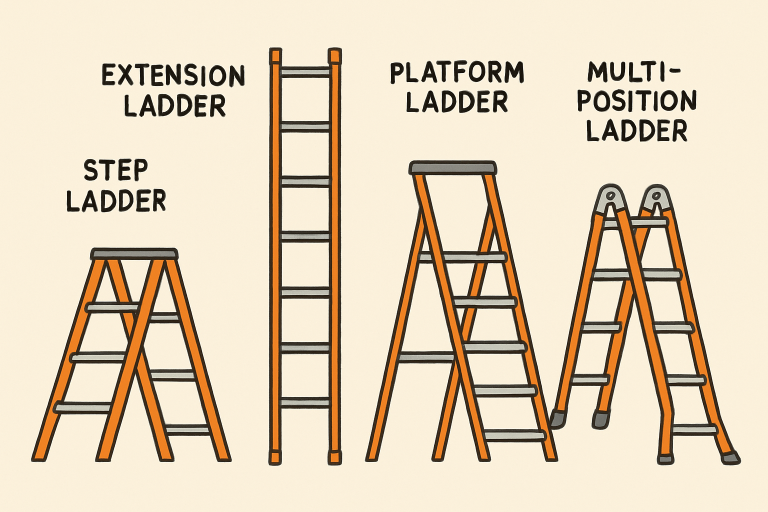

The diversity of workplace activities calls for a variety of ladder types, each specifically designed for certain applications:

- Step Ladders: These freestanding ladders are a staple for tasks where stability and portability are equally important. They typically feature a folding design, making them suitable for quick, light work and frequent movement.

- Extension Ladders: Unlike step ladders, extension ladders require support against a surface. Their extendable section lets users reach significant heights, making them ideal for maintenance, exterior projects, or accessing rooftops and high shelves.

- Platform Ladders: Featuring a sizable standing area at the top, platform ladders offer increased comfort and stability for tasks requiring both hands, such as electrical work or stocking.

- Multi-Position Ladders: These flexible ladders adapt into various configurations—step, extension, or scaffold—catering to a wide range of onsite challenges and providing a valuable, all-in-one equipment solution.

Each type serves uniquely to boost productivity and safety, underscoring the need to match ladder design with specific job demands.

Key Factors in Ladder Selection

Choosing the appropriate ladder involves evaluating several key factors:

- Height Requirements: The selected ladder must allow for overhead work without requiring overreaching or standing on the top step/rung, which increases the risk of falling.

- Load Capacity: Always account for the combined weight of the user, tools, and materials. Overloading ladders can result in structural failure and severe injuries.

- Material: Ladders are commonly made from aluminum or fiberglass. Aluminum ladders are lightweight and easy to move, but fiberglass is the preferred choice where electrical hazards exist due to its non-conductive properties.

- Duty Rating: Ladders are rated for maximum load—Type I (250 lbs), Type IA (300 lbs), and so on. Choose a duty rating that covers users’ weights and the demands of the job environment.

Making informed choices on these fronts helps ensure operational efficiency, limits downtime, and directly addresses safety requirements at multiple levels of the organization.

Safety Standards and Compliance

Regulatory compliance is foundational for workplace safety. The Occupational Safety and Health Administration (OSHA) establishes comprehensive requirements for ladders in the workplace, encompassing design and construction, as well as usage and inspection procedures. According to OSHA standards, portable ladders must have side rails that extend at least three feet above the landing surface, and ladders must be regularly inspected and maintained. Non-compliance not only endangers workers but also exposes businesses to potential fines and legal liabilities. To learn more, read about Top Trail Safety Tips for Hikers.

Inspection and Maintenance Best Practices

Routine and thorough inspection of ladders is essential for a safe worksite. Every use should be preceded by a quick check for:

- Signs of structural weakness, such as cracks, deformation, or corrosion on ladders and joints.

- Loose, damaged, or missing steps and rungs that could lead to slippage or collapse.

- Malfunctioning or unsecured locking mechanisms, particularly on extension or platform ladders.

- Accumulated oils, dirt, or other contaminants on steps can greatly increase the risk of slips and falls.

Ladders with visible defects should be removed from service immediately and either repaired by qualified personnel or replaced entirely to avoid avoidable incidents.

Training and Proper Usage

Continuous training is crucial for preventing ladder-related injuries. Employees should be educated regularly on core principles, such as:

- Maintaining three points of contact provides optimal balance and support during ascent or descent.

- Ensure ladders are positioned on stable and level ground before use, thereby reducing the risk of tipping.

- Always face the ladder while going up or down, and never carry heavy items in your hands when climbing.

- Avoiding overreaching, which can shift weight distribution dangerously and potentially lead to falls.

Effective safety programs incorporate both onboarding and refresher training to embed safe ladder practices throughout the entire workforce.

Alternatives to Traditional Ladders

Certain tasks or environments demand solutions that go beyond traditional ladders. Examples of alternative equipment include:

- Scaffolding: Ideal for projects that require an extended work duration or cover broad areas. Scaffolding provides superior stability and a greater working area.

- Mobile Elevating Work Platforms (MEWPs): These devices offer versatility in height and positioning with enhanced mobility. Perfect for large-scale industrial, maintenance, or construction work.

- Work Platforms: Providing a stationary, secure, and comfortable base at height, work platforms are invaluable for repetitive tasks that must be performed overhead.

Assessing the complexity and risks associated with each task will enable your team to select the safest and most suitable equipment, thereby preventing unnecessary accidents and enhancing productivity.

Conclusion

Prioritizing the right commercial ladder is a cornerstone of workplace safety and risk management. Through a comprehensive understanding of ladder types, duty ratings, regulatory requirements, inspection routines, and ongoing employee education, organizations can ensure staff safety and productivity. Staying informed about alternatives and updating equipment as needed further solidifies a safety-first culture, protecting both employees and the company’s reputation in the long term.